Description

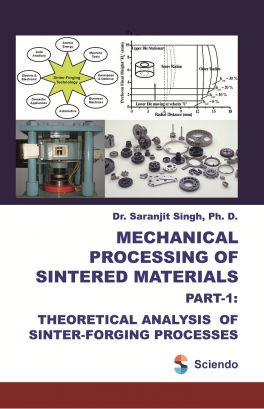

Mechanical processing of sintered materials in the form of metal powder preforms includes techniques such as sinter-forging, sinter-extrusion, sinter-rolling etc. One technique, which has aroused interest globally for producing high performance components economically, is sinter-forging, which combines the advantages associated with powder metallurgy and conventional forging techniques. The process is attractive because it avoids large number of operations, high scrap losses and energy consumption associated with conventional manufacturing processes. The technology, though have been extensively applied throughout the world for manufacture of numerous components, still requires to be explored from several perspectives. The objective of the present book is to study, explore and investigate the deformation characteristics during mechanical processing of the sintered materials.

ABSTRACTING & INDEXING

Mechanical Processing of Sintered Materials is covered by the following services:

Baidu Scholar

Bayerische Staatsbibliothek

BDS

Bowker Book Data

Ciando

CNKI Scholar (China National Knowledge Infrastructure)

Dimensions

EBSCO

ExLibris

Google Books

Google Scholar

Naviga

ReadCube

Semantic Scholar

TDOne (TDNet)

WorldCat (OCLC)

X-MOL

Additionally, the proceedings volume is registered and indexed in the Crossref database and accessible on Amazon.

TOC

- ACKNOWLEDGMENT 4

- PREFACE 5

- CONTENTS 6

- LIST OF FIGURES 7

- LIST OF TABLES 14

- NOMENCLATURE 15

- Chapter 1: Introduction 18

- Chapter 2: Basic Experimental Analysis during Sinter Forging 34

- Chapter 3: Open Die Forging of Sintered Preforms 64

- Chapter 4: Close Die Forging of Sintered Preforms 102

- Chapter 5: Rotary Forging of Axi-Symmetric Sintered Powder Preform 122

- Chapter 6: Design of Experiment (DOE) Application in Sinter Forging 138

- APPENDICES 153

- REFERENCES 170